Solarplate Troubleshooting Guide

Problem: When washing out the plate, everything washed away.

Cause: Insufficient exposure

Solution: Increase exposure

Problem: When washing out the plate, not enough washed away

Cause: Too much exposure

Solution: 1) Decrease exposure. 2) Increase washing time. 3) Wash in area without daylight.

Problem: Plate Sticky

Cause: Insufficient post-exposure.

Solution: Post-expose again.

Problem: Not enough detail in print

Cause: Transparency not opaque enough; Transparency upside-down.

Solution: 1) Use more opaque image-making materials 2) Turn Transparency emulsion to emulsion.

Problem: “Open-bite” effect

Cause: Image too dense.

Solution: 1) Longer exposure. 2) Shorter washout & blot with fabric before washing to bottom of polymer layer. 3) Use double exposure technique with screen

Problem: Scratches in plate

Cause: Washout brush may be too rough.

Solution: Use softer bristle.

Problem: Water spots on plate

Cause: Water residue not dried quickly.

Solution: Blot immediately and dry with hair drier after washout.

Problem: White spots on plate

Cause: Acetate & photocopy characteristic

Solution: 1) Better contact with vacuum may help; however, there may not be a solution. 2) Try heavier weight acetate. 3) Dust emulsion side of film with talc. 4)Change the brand of acetate.

Problem: Black spots on plate

Cause: Drawing dust or dirt.

Solution: Brush transparency or clean exposure glass.

Problem: Drawing material transfers to plate

Cause: India ink, certain pencils combined with pressure and heat.

Solution: Dust drawing with talc or baby powder.

Problem: Circumference of plate shows irregularity in tone

Cause: Exposure unit with vacuum frame

Solution: 1)Use slightly smaller transparency and trim Solarplate 2)decrease the bleed on the vacuum

Problem: Parts of plate are blurred or ill-defined

Cause: Contact between plate & transparency too tight or too rigid or shifting may have occurred

Solution: 1) Use more efficient clamps or vacuum or use different transparency. 2) Use backing foam or cloth.

Problem: Plate curls when stored

Cause: Improper storage

Solution: Store plate w/h thin layer of oil/ kerosene in plastic; weighted with books etc.

Problem: When washing out, there is no apparent artwork on the plate

Cause: Screen is so fine, it may not be visible

Solution: Blot dry with newsprint and examine again.

Problem: When washing out, there was open biting

Cause: The screen was not exposed long enough, or was not place emulsion side down

Solution: Expose the screen longer

Problem: The print was too light

Cause: the work was over exposed : the screen may have been placed upside down

Solution: Do another exposure with shorter timing, place the screen emulsion to emulsion

Problem: The print was too dark

Cause: the work was under exposed

Solution: do another exposure with longer timing

Double exposure guidelines and trouble shooting:

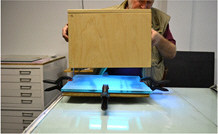

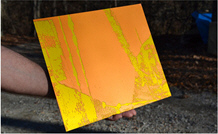

Since the double exposure technique is one which requires much more experimentation, it is important to understand the principle of the aquatint screen. When exposing the plate to the screen each exposure unit differs as does the sun. Therefore, TEST FIRST! Expose a small plate to the screen in a step scale with varying times. Wash out the plate and print it. If you find for example that it works with 90 seconds, you might try exposing your artwork for the same amount of time. If you have a dense artwork give it longer; a thin artwork would necessitate shorter